IC inspection & Taping machine

(IC inspection & Taping machine)

| Objects products: | 4mm~15mm |

|---|---|

| Processing speed: | 0.64 s/pc ±10% |

| Jam rate: | 0/3000 pcs |

| Inspection surface: | Face or back |

| Inspection content: | Lead, Mark, PKG |

| Capacity inspection: | 100μm×100μm |

| Capacity measurement: | 10μm3Σ |

Operation route:

Put trays of products to Loader.

Tray is moved to separation unit and product is separated one by one to inspection stage.

Camera will capture image of product then inspect.

If the inspection of product is OK, it will be moved to emboss tape then seal.

If the inspection of product is NG, it will be rejected to NG tray.

Function of machine and some NG samples which machine detected.

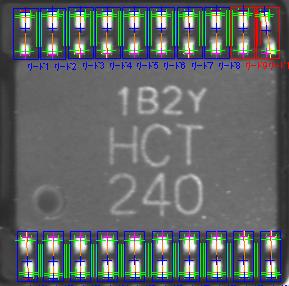

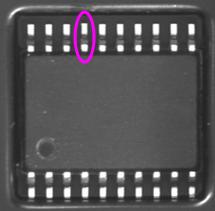

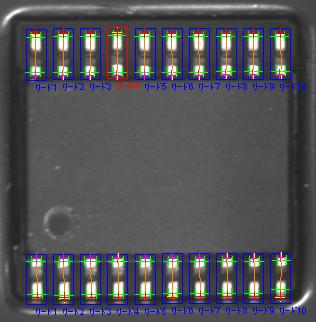

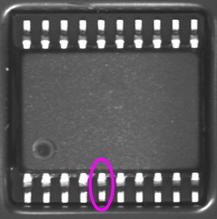

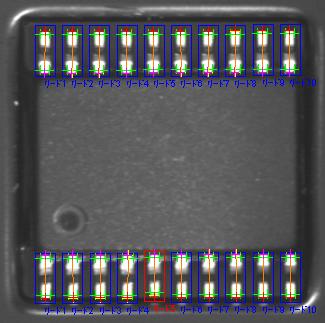

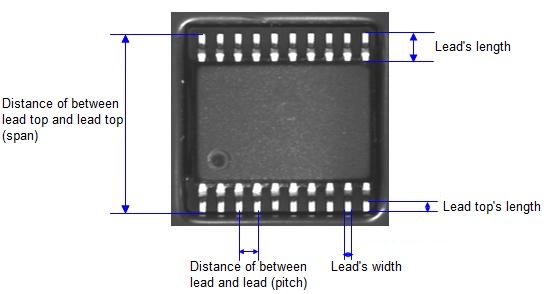

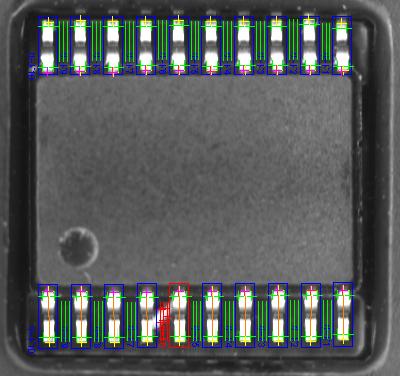

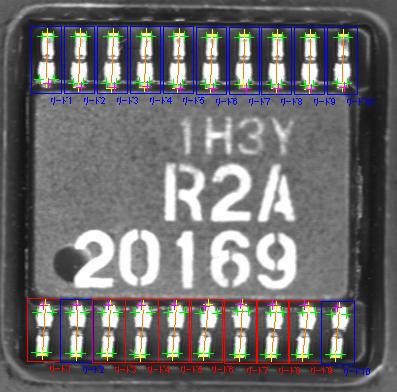

Lead inspection:

Bended lead, lead's length, lead's width, distance of between lead and lead (pitch), lead top's length,

rubbish on between lead and lead, bended whole row of lead, redundant lead.

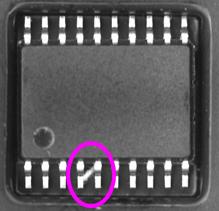

Bended lead

Coplanarity (floating)

Coplanarity (sinking)

Measure distance of lead

Rubbish on between lead and lead

Bended whole lead on row

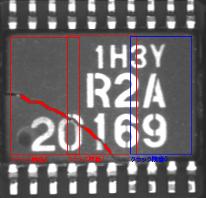

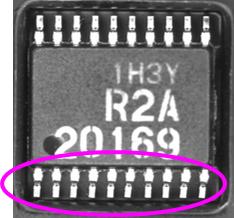

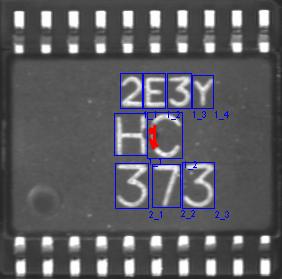

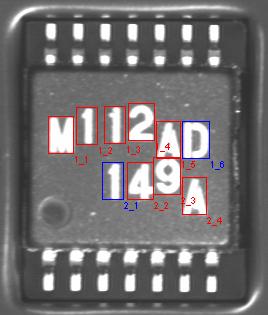

Mark inspection:

Inspecting thin mark, chipped mark, No mark, mixing mark

Distance of marks, askew mark.

Distance of marks, askew mark.

Thin mark, chipped mark

Askew mark

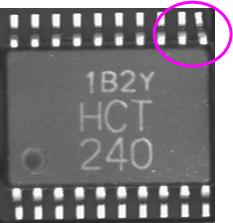

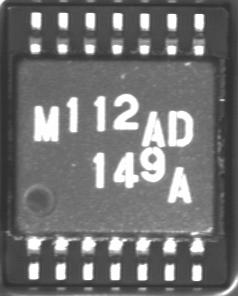

PKG inspection:

Inspecting scratch, chip, crack

Scratch

Crack